3D printing has emerged as a groundbreaking sustainable method of producing light fittings. Prusa 3D printers are the standout machine on the market, and DRK Lighting were so impressed we bought half a dozen of them. James, our very own 3D Czar, is busy as a bee designing and printing some amazing new downlight concepts. He is kicking up a storm here at our Chessington Factory, which he reminds us is now also known as a farm in the 3D printing world.

Prusa 3D Printer

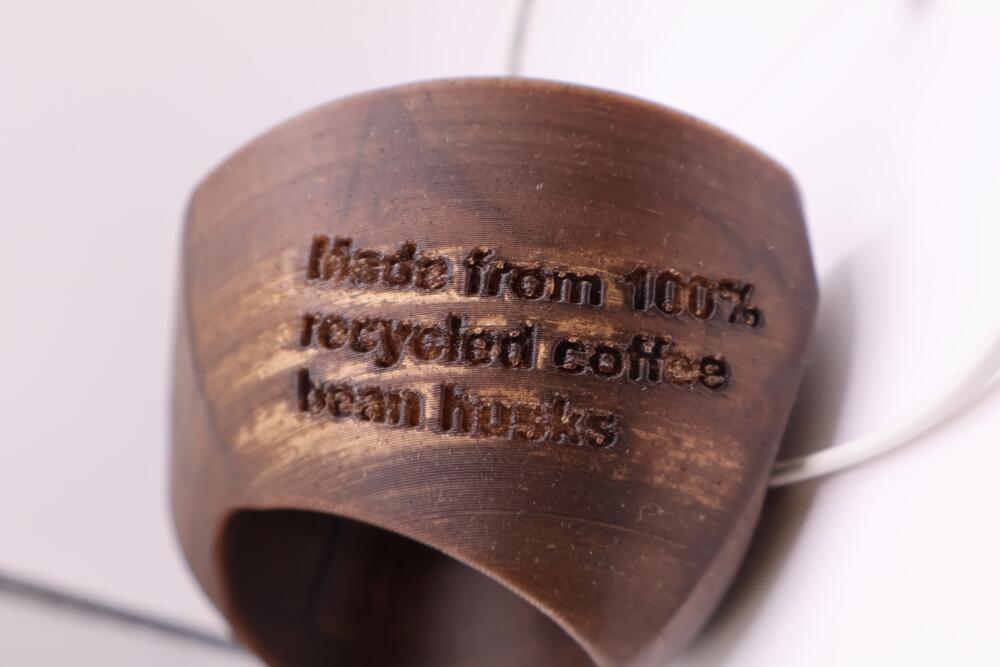

The Coffee Beam

DRK Lighting’s 3D Printing Czar James (we use his entire title when we want his attention) has made demands that we have willingly followed. Now, DRK 3D Printing has its own lab space, which is kept warm for optimum conditions. His first creation, fresh off the bed, is a downlight prototype with an even more environmentally conscious twist. It’s made from used coffee bean husks. It also has 3 beam angles, and he has aptly named ‘The coffee beam’. James is disputing it, but we think he got the name from Greta, our Head of Sustainability (let’s keep this to ourselves). With The Coffee Beam, we have reduced waste and repurposed what would otherwise be discarded into a valuable resource.

This innovative 3D farm approach minimises the need for raw materials, significantly lowering the carbon footprint associated with traditional manufacturing methods. The precision of 3D printing allows for efficient use of materials, reducing excess waste while ensuring the durability and aesthetic appeal of the final product.

At DRK, we’re excited to combine cutting-edge technology with sustainable practices, creating beautiful, eco-friendly lighting solutions that help to light a more sustainable future by utilising the past. Coffee husks now light our coffee mugs.