At DRK Lighting, we are committed to advancing sustainability in every aspect of our business, which is why we continually invest in cutting-edge technologies that drive innovation. We are excited to share our latest creation, the White Cube Space, a bespoke, fit-for-purpose facility currently in progress. This high-tech lab will be a six-figure investment for DRK, enhancing our remanufacturing capabilities and elevating our position as leaders in the Lighting Remanufacturing sector.

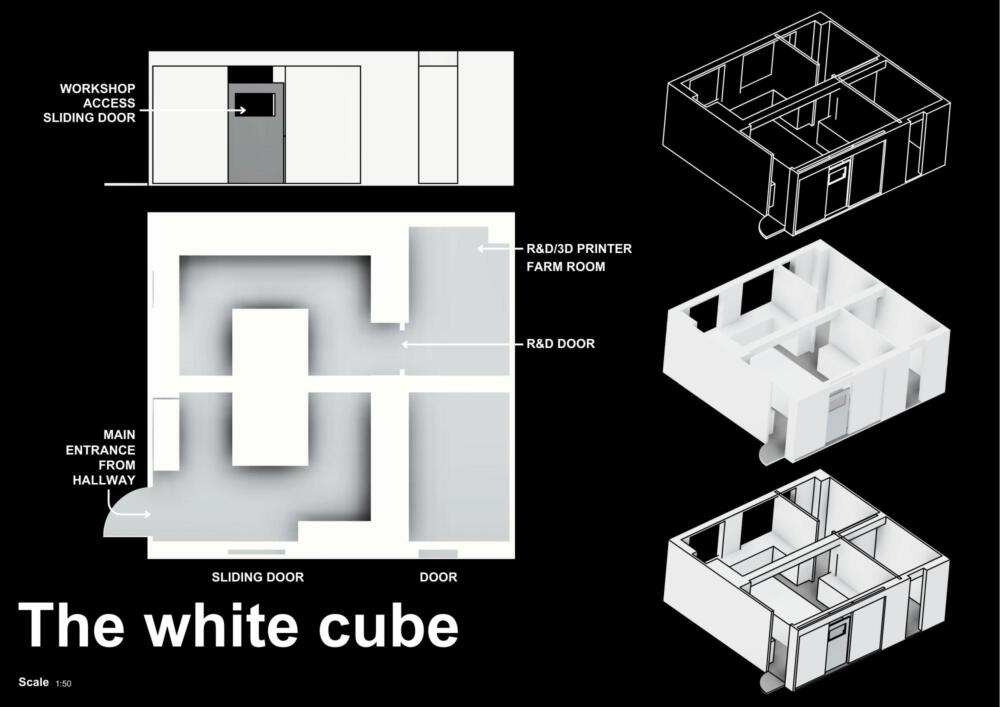

The White Cube CAD drawings

The White Cube will streamline every phase of the remanufacturing process, from disassembly to final testing, allowing us to refine our processes and create high-quality, sustainable lighting solutions. The space will be carefully organised into distinct zones, each tailored to a specific task, ensuring a smooth and efficient workflow.

As you enter the facility, you’ll find a well-lit area featuring advanced equipment for carefully disassembling light fittings. Dedicated tools will be available to safely remove internal components such as wiring, ballasts, and lenses. Each workstation will be ergonomically designed, with adjustable benches and storage for tools and parts, minimising downtime and maximising productivity.

A cleaning station will feature an ultrasonic bath for cleaning, dust removal, and polishing, restoring fittings to a near-new condition. The lab will also include a testing zone equipped with state-of-the-art diagnostic tools and equipment that simulate real-world conditions, such as temperature and humidity variations, ensuring that all remanufactured products meet the highest safety and efficiency standards. Our 3D modelling software allows us to explore the designs in detail and flag any conflicts that may become evident further on in the process. The latest version of Metrel electrical earth testing safety equipment has been delivered, and other additions will include our in-house LED photometric equipment to test luminous flux measurements.

DRK’s Ultrasonic Bath

Dedicated machining and calibration stations will be available for parts requiring precision modifications or replacements, including advanced laser cutters, 3D printers, and calibration tools. These stations will enable us to create custom replacement components with high accuracy and minimal waste. A materials recovery area will sort, clean, and reuse recyclable components, contributing to a circular economy and reducing environmental impact.

The lab will feature a controlled climate area for storing sensitive components, ensuring that parts like LEDs, drivers, and other electronic elements remain in optimal conditions before installation. Air filtration and ventilation systems will maintain a clean, safe working environment, preventing the spread of contaminants and ensuring a secure atmosphere for our remanufacturing technicians.

With 24-hour monitoring capabilities, the White Cube will record all actions within the space for playback and observation, allowing us to track the journey of luminaires as they are transformed from near-obsolescence into products fit for the future. All components will be tagged with individual passports to make it easy to identify and reorder parts when necessary.

DRK Chessington’s ‘The white cube’ sign

Our remanufacturing process is designed to prioritise waste reduction and ensure that products meet or exceed their original specifications. This process includes collection, assessment, disassembly, cleaning, reprocessing, and reassembly, followed by rigorous testing and recertification. Services offered include converting incandescent fittings to LED, replacing damaged components like glass and wiring, and upgrading lighting systems with technologies such as DALI controls or Bluetooth.

The White Cube will support DRK Lighting’s mission to lead in sustainability and innovation, enhancing our capacity to deliver high-quality remanufactured products while contributing to a circular economy. By extending the lifecycle of lighting products, we’re helping to reduce waste and ensure that our customers receive high-performance, sustainable solutions. DRK Lighting’s desire to ‘Light the Future with the Past’ is helping to change the sustainability conversation spearhead and concentrate less on ‘new’ and more on ‘renew’.

To learn more about our Remanufacturing processes, head to our dedicated remanufacture page: https://drklighting.co.uk/remanufacture/.